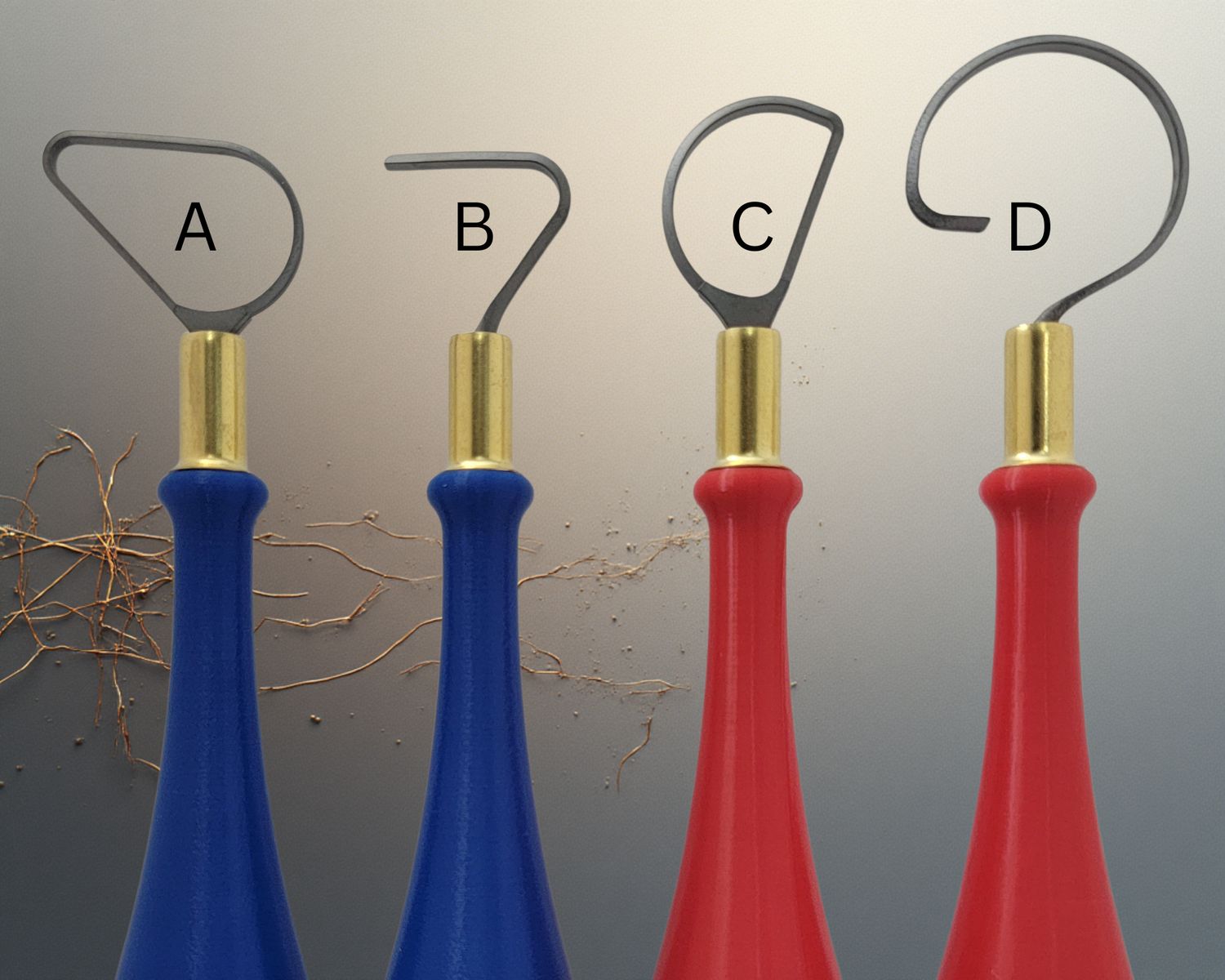

Carbide Trimming Tools for Pottery and Ceramics

Choose from four different styles or buy a combo! Our custom designed, real-world tested PETG carbide tools aren't just resilient; they're ergonomic. They're light as a feather, and the handles are 3D printed to be strong and rigid. They get the job done right and they feel good in the hand. We found that short, stout handles give potters an ideal grip and refined control. The brass collar adds strength and will never rust. Best of all, the tungsten carbide cutting heads will outlast traditional metals by an order of magnitude. The difference really is hard to exaggerate.

About carbide:

Tungsten carbide has been used in machining and manufacturing for decades. Its hardness is infamous. In the world of metalworking, it can withstand hours and hours of abrasive abuse under insane stresses. And the edge will stay as sharp as ever.

Carbide is a very unique material, holding an edge for years. That also means it's more difficult to produce and thus more expensive. Carbide must be milled into a powder, mixed with cementing materials, and cast into shape under high pressure. It's then cured in a kiln. Other metals can simply be bent into a particular form, but not carbide. This hardness, unfortunately, also means that extra care must be taken during use and storage: carbide tools must never be dropped or used to pry. They will shatter like glass! However, this same hardness is what gives its sharp edges such staggering longevity.

It can be sharpened, but you'll never need to. This is the same material machinists use to cut cast iron and stainless steel -- two of the most onerous materials in production. For potters, our onerous material is GROG -- because it's essentially ground up glass remixed into our clays to add structural stability. Grog is what dulls our traditional tools so quickly.

But it won't dull carbide! These tools will cut through leather-hard clay like butter.

Give your style an octane boost and upgrade to carbide.

100% Waterproof. Made by hand right here in the USA! Questions? Feel free to message us!