Shellbark Hickory Handmade Wooden Handled Carbide Trimming Tools for Pottery and Ceramics Wood

We are thrilled to finally offer wooden handles! Beautiful wood salvaged from our property after a storm: This is gorgeous shellbark hickory rescued after an ice storm.

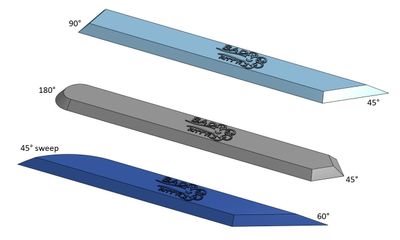

When you order, you receive both of these tools. These cannot be sold individually. For individual tools, please see our carbide tools with 3D printed handles, where you have the option to select one or more. Again, the pictures you see are the exact tools you are buying, not just stock photos of something similar.

Our wooden handles are extra-long for added control. First, we turn them to a uniform shape on our CNC lathe, then sand by hand. The luster you see in the pictures is our exterior hard coating. Unlike mainstream handles, ours aren't just polished with wax. They're sealed with seven layers of cyanoacrylate (just a fancy word for industrial super glue) and then sanded incrementally up to 3000 grit for a mirror shine that will last years. This protective coating is 100% impervious to water. No staining. No warping. No cracking.

The blue aluminum collars are anodized in a series of chemical baths that produce their own hardened coating for protection, then dyed to add a flash of lasting color that compliments the chosen wood. These aluminum collars resist scratching and oxidation (though they can and will scratch over time). Best of all, the tungsten carbide cutting heads will outlast traditional metals by an order of magnitude. The difference really is hard to exaggerate.

About carbide:

Tungsten carbide has been used in machining and manufacturing for decades. Its hardness is infamous. In the world of metalworking, it can withstand hours and hours of abrasive abuse under insane stresses. And the edge will stay as sharp as ever.

Carbide is a very unique material, holding an edge for years. That also means it's more difficult to produce and thus more expensive. Carbide must be milled into a powder, mixed with cementing materials, and cast into shape under high pressure. It's then cured in a kiln. Other metals can simply be bent into a particular form, but not carbide.

It's this hardness that gives its sharp edges such staggering longevity. It can be sharpened, but you'll never need to. This is the same material machinists use to cut cast iron and stainless steel -- two of the most onerous materials in production. For potters, our onerous material is GROG -- because it's essentially ground up glass remixed into our clays to add structural stability. Grog is what dulls our traditional tools so quickly.

But it won't dull carbide! These tools will cut through leather-hard clay like butter.

Give your style an octane boost and upgrade to carbide.

100% Waterproof. Made by hand right here in the USA! Questions? Feel free to message us!